Welding Fume Extraction Upgrade for City of Liverpool College

- Client: City of Liverpool College – Vauxhall Road Campus, Fabrication Department (G/20/1)

- Process: Mild Steel (MIG) Welding

- Hazard Controlled: Welding Fume (mixture of metal oxide compounds & gases)

The Challenge

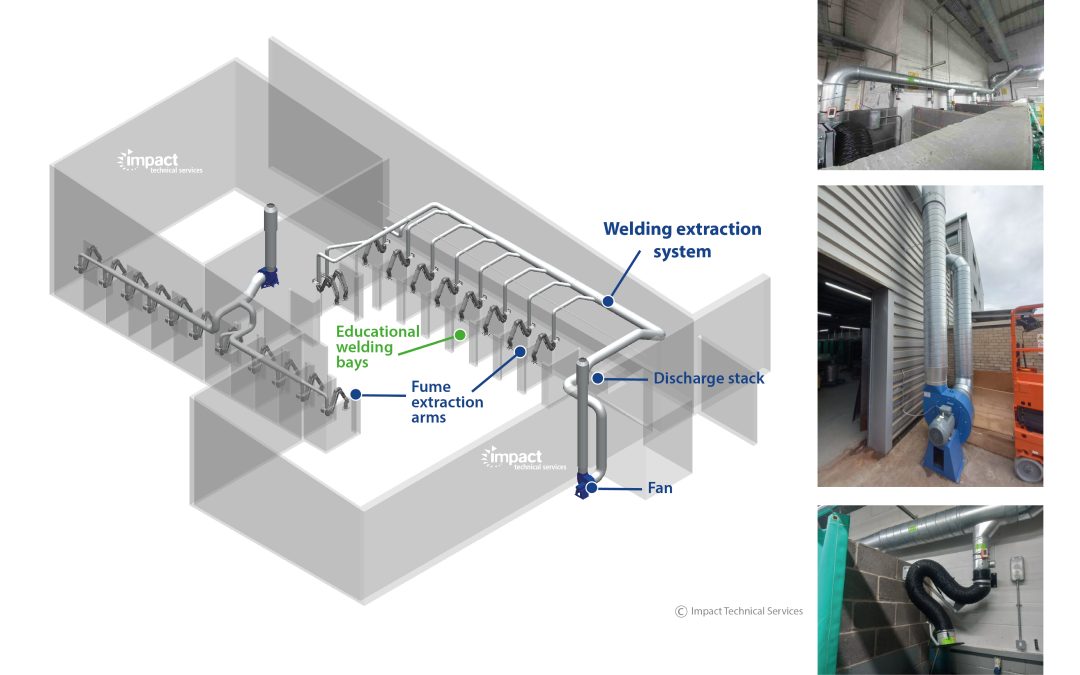

The welding bays at the college’s fabrication department were in regular use by students training in MIG welding techniques. However, the original fume extraction system was outdated and failing to adequately remove harmful airborne contaminants from the working environment. With 10 welding bays in operation, several extraction arms required replacement, and additional arms needed to be installed to ensure safe and compliant fume control.

Our Solution

Impact Technical Services supplied, installed, and commissioned a dedicated welding fume extraction system to serve all 10 bays. The design was fully compliant with HSG258 – Controlling Airborne Contaminants at Work, applying:

- Capture velocity: 0.5 m/s at 200mm from source

- Minimum duct velocity: 10 m/s

Each extraction arm was positioned for maximum accessibility and capture efficiency, ensuring students could weld safely without exposure to excessive fumes.

Hazard Profile & Exposure Limits

Welding fume is a complex mixture of metal oxide compounds and gases. While there is no single Workplace Exposure Limit (WEL) for welding fumes, several constituent WELs apply:

- Nickel (as Ni): 0.1 mg/m³ TWA – Carcinogenic

- Iron Oxide Fume (as Fe): 5 mg/m³ TWA

- Manganese (as Mn): 0.2 mg/m³ TWA – Can cause neurological effects

The system was engineered to effectively control these hazards in line with the latest HSE guidance.

Commissioning & Compliance

Upon completion, the installation was commissioned by one of Impact’s P601/P604-certified technicians. A full commissioning report and documentation were issued, confirming compliance with HSG258 and providing the college with clear records for ongoing LEV management.

The Result

- Improved air quality and student safety in all welding bays

- Full compliance with HSE welding fume control requirements

- Future-ready system capable of adapting to evolving safety standards

LEV Solutions for Education

We provides LEV testing, installation, and maintenance for schools, colleges, and universities nationwide — keeping training environments safe and compliant.