Client Overview

Progress Rail, part of the Caterpillar company, is a leading global supplier of rail products and services. Their Sandiacre facility undertakes extensive welding and engineering work, where maintaining a safe and efficient working environment is crucial. Impact Technical Services has supported Progress Rail for many years by maintaining their LEV equipment across the site.

The Challenge

During routine operations, an issue arose where excessive welding fume from a Schotler Butt Welder was creating an unpleasant cloud in the workshop. This posed a health risk to operators, reduced air quality, and highlighted the need for a more effective extraction solution.

Our Solution

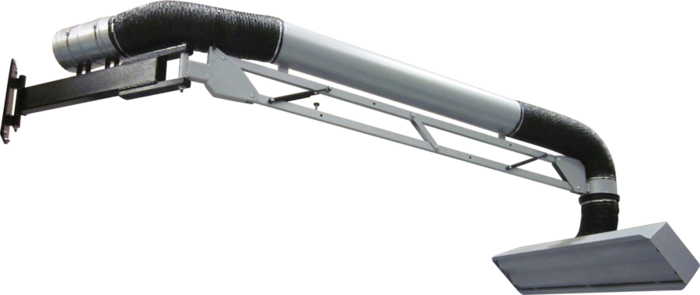

Impact Technical Services designed and installed a new LEV system to effectively capture and extract the welding fume. Key considerations included:

- Routing the ductwork around the overhead crane system.

- Correctly sizing the fan and ductwork in line with HSE guidance (HSG258).

- Installing the fan at a low level for easy access and maintenance.

- Coordinating with specialist contractors to install a high-velocity cowl on the roof for safe discharge of contaminants above the building’s boundary layer.

The Result

The new system successfully removes hazardous welding fumes, creating a safer, cleaner working environment for operators while meeting HSE compliance standards.

Find out more about our fume extraction solutions here.