Client Overview

A leading sports nutrition manufacturer recently opened a new production site in Speke. With rapid growth and high production demands, they needed to ensure effective dust control to protect product quality, maintain a safe working environment, and meet strict food-grade industry standards.

The Challenge

At the new facility, the manufacturer faced the challenge of managing fine airborne dust generated during various stages of production, including weigh rooms, rip & tip stations, filling lines, and a Syspal processing area. The site needed a COSHH-compliant dust extraction system that could manage current production levels and allow for future expansion. Key priorities included reducing operator exposure, meeting safety standards, and keeping the processing areas clean.

Our Solution

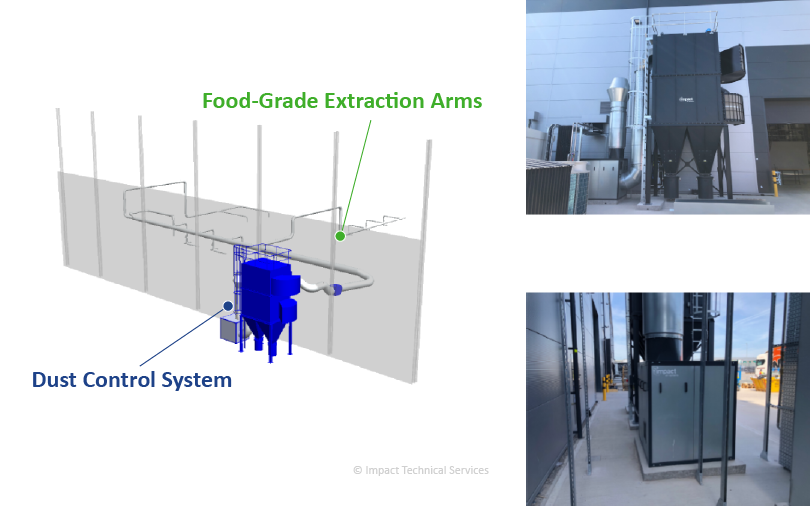

Impact Technical Services designed, supplied, and installed a fully integrated ATEX-rated dust extraction system tailored to the Speke site’s operational layout. The solution included:

- Smooth-bore ductwork system with strategically placed hoods and food-grade extraction arms to capture dust at source across 3 weigh rooms, 3 filling lines, 2 rip & tip stations, and Syspal enclosures.

- A 164m² automatic tubular bag filter equipped with antistatic glazed polyester media, reverse jet cleaning system, and dust collection hoppers for efficient filtration.

- ATEX-certified safety features, including:

- FLEX R4 flame quench devices for explosion mitigation.

- Explosion back draught damper to prevent return shockwave through ductwork.

- A Zone 22/22 centrifugal fan in an acoustic enclosure with inline attenuators for quiet operation.

- Built-in futureproofing, with spare capacity for additional rip & tip stations and filling lines, including duct branches and dampers for future connections.

- Optional extras such as airflow indicators and a custom control panel for enhanced monitoring and safety compliance.

The installation was completed in approximately four weeks, managed and commissioned by our expert engineering team.

The Result

The new LEV system at the Speke site now delivers 17,450 m³/hr of airflow, providing effective dust control throughout the production process. Air quality has been significantly improved, operator exposure is reduced, and the system is compliant with both COSHH and ATEX regulations. With scope for future expansion built in, the system is ready to grow with the business.

Ongoing Support

To ensure continued performance and regulatory compliance, we offer ongoing servicing, system optimisation, and LEV testing every 14 months. By choosing our aftercare support, the manufacturer can ensure long-term operational efficiency and uphold workplace safety standards.

Find out more about our Dust Control Systems here.