Client Overview

A leading multi-services contractor providing electrical, mechanical, maintenance, air conditioning, refrigeration, and fire systems.

The Challenge

The contractor operates a jerrican reparation shed where waste fuel jerricans — containing petroleum, diesel, and potentially contaminated substances — were decanted. The process posed significant risks of explosive vapours and inhalation hazards.

Our Solution

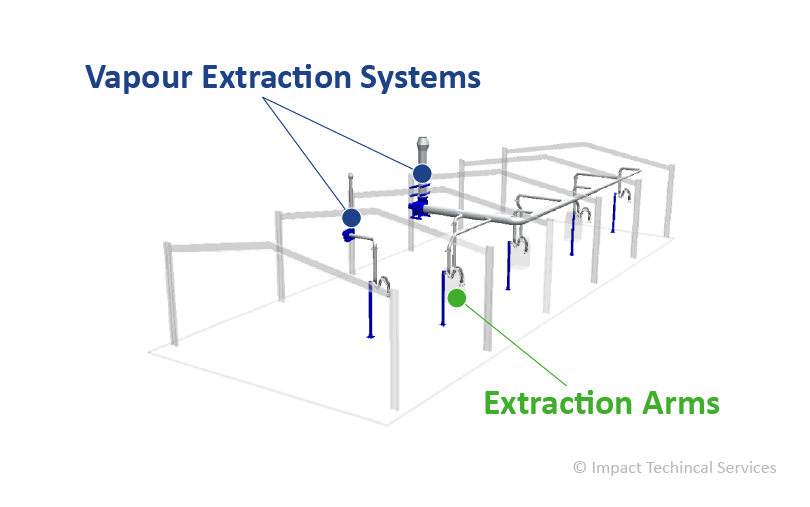

To address this challenge, we designed, supplied, delivered, and installed two bespoke ATEX vapour extraction systems. These systems were engineered to control the vapours produced during the fuel decanting process, significantly reducing the risk of explosion while also improving air quality for operators. The first system features a high-level centrifugal fan connected via galvanised steel ductwork to five articulating extraction arms, each fitted with circular capture hoods positioned above three back-to-back fuel hoppers.

The entire system, including the fans, ducting, and arms, is fully ATEX rated to meet the stringent safety requirements of the environment. The second system is similarly configured, consisting of a high-level centrifugal fan and galvanised ducting leading to a single articulating extraction arm with a circular capture hood. Like the first, it is fully ATEX rated, offering robust protection in a smaller workspace.

The Result

Both systems are now fully operational and delivering effective vapour control. The contractor benefits from a safer, more compliant working environment with reduced exposure risk for staff and significantly lower potential for explosive atmospheres.

Ongoing Support

Following installation, we continue to support this customer with optional LEV testing every 14 months, service and maintenance packages, and a reliable supply of spare parts — ensuring long-term performance and peace of mind.

Find out more about our ATEX range here.