Client Overview

A manufacturer of forming sets for food and pharmaceutical packaging machines required a safe, compliant solution to control TIG welding fumes produced during daily operations.

Our Solution

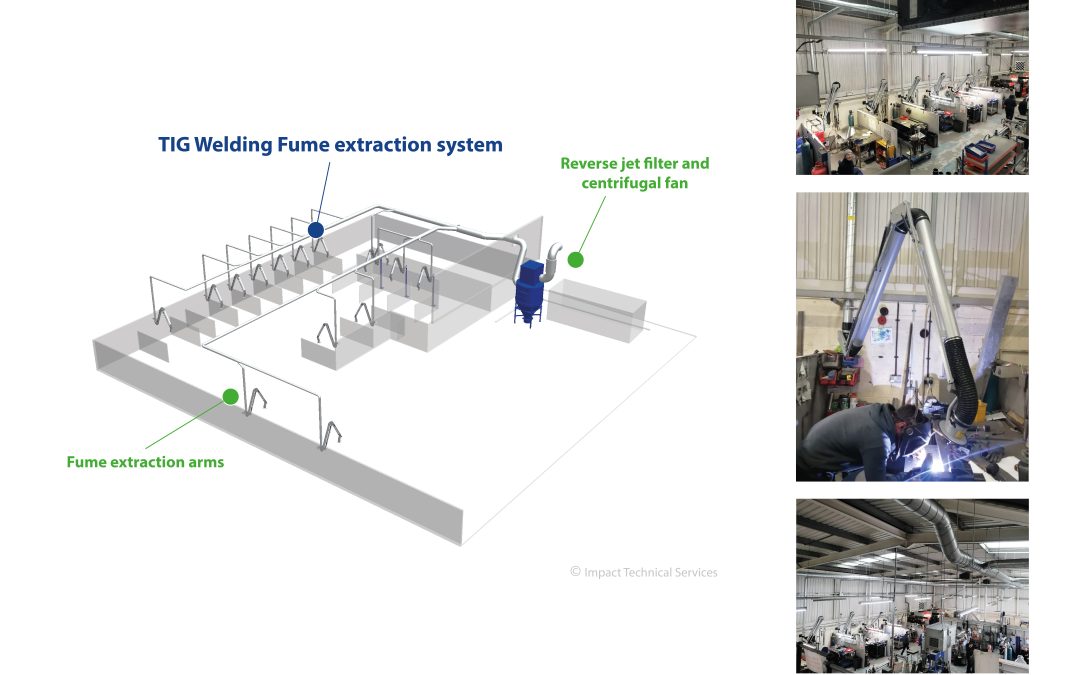

We installed a centralised LEV system for TIG welding operations consisting of:

-

13 RFF 4000/125 articulating fume extraction arms with 360° swivel connections for operator flexibility and flow-optimising flanged hoods with open/close dampers for precise fume capture.

-

Spirally wound, hot-dip galvanised steel ductwork (BSEN 10327:2004, HVCA DW144 compliant), installed at 3.5–4m height and supported with Unistrut framing.

-

External ACF-T 234H/W3 reverse jet cyclonic filtration unit with G115A high-efficiency filter media and a 15kW centrifugal fan for powerful airflow and filtration.

The system was commissioned by a P601/P604-certified technician in line with HSG258.

The Result

The LEV system now provides effective fume capture at source, ensuring greater operator safety and comfort, full compliance with workplace exposure limits, and long-term, reliable performance.

Find out more about our fume extraction solutions here.