Client Overview

A leading manufacturer of heated display units and insulated steel panels operates a CNC workshop in Hinckley. During the routing process, the panels generate fine airborne dust, which requires effective extraction to maintain a clean and safe working environment.

The Challenge

The manufacturer’s existing dust extraction system was no longer sufficient to manage the volume and type of dust produced by their four CNC routers (two single-head and two double-head machines). The system needed an upgrade to handle both PIR dusts and mild steel dusts effectively while meeting air quality standards and keeping up with the demands of the CNC routing process.

Our Solution

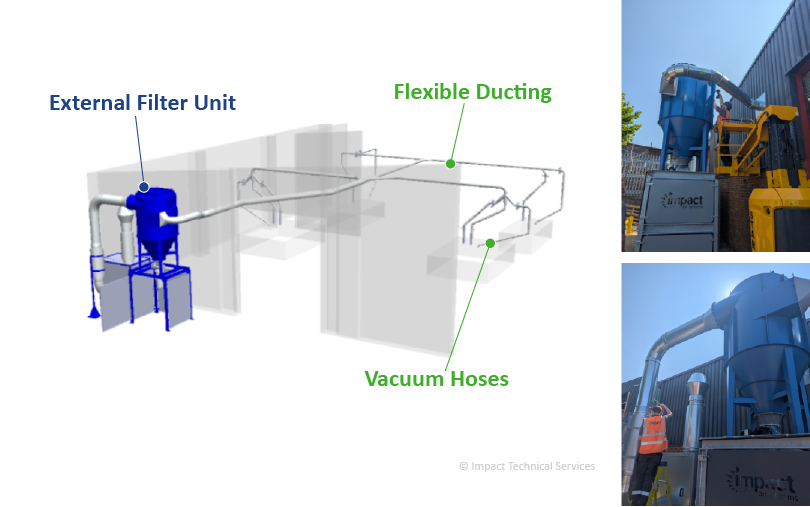

We supplied and installed a new high-performance dust extraction system tailored to the CNC workshop’s needs. The system features:

- An ACF-T 130H external filter unit equipped with G113 antistatic filters (Dust Class M) for reliable filtration of fine dusts.

- A 30kW AB fan to ensure consistent extraction power across all routers.

- Flexible ducting connecting the extract hoods to a common 300mm header duct, allowing full movement across the router beds.

- Supplementary vacuum hoses at each CNC station to assist with cleanup of swarf and larger particles.

- Analogue pressure gauges installed on each hood to monitor performance, calibrated and marked by our commissioning engineer.

We utilised some of the existing ductwork to reduce waste and costs, ensuring a cost-effective, efficient installation with minimal disruption.

The Result

The new extraction system is now fully operational and delivering excellent dust control across all four CNC routers. With extraction velocities of over 22 m/s at each pickup point and over 25 m/s in the vacuum lines, the system ensures the workshop remains clean, safe, and compliant with workplace exposure limits.

Ongoing Support

The manufacturer can rely on our ongoing support services, including system maintenance, spares, and scheduled LEV testing every 14 months to ensure continued compliance and performance. We’re proud to support manufacturers in maintaining safe and efficient operations.

Find out more about our dust control solutions here.