LEV Testing

UK Nationwide, HSE Compliant

We offer comprehensive LEV testing services across the UK, serving all industries. Protect your workforce and stay compliant with BOHS-certified (P601, P602, P603, and P604) LEV testing.

Local Exhaust Ventilation Requirements

Why LEV Testing Matters

LEV testing is a legal requirement under the UK’s COSHH Regulations, created to protect workers from exposure to hazardous airborne substances. Substances such as dust, fumes, oil mist and vapours can cause long-term health issues if not properly controlled, making a compliant extraction system essential for workplace safety.

Regular testing ensures your LEV system continues to perform as designed, keeping employees safe, maintaining compliance, and avoiding costly downtime. It also provides employers with peace of mind, knowing their workplace meets HSE standards and is protected from enforcement action.

Key requirements:

- Must be carried out at least once every 14 months (COSHH Regulation 9)

- Prevents exposure to dust, fumes, mists, vapours and other airborne contaminants

- Protects your business from HSE fines, legal penalties, and unexpected downtime

Book Your LEV Test Today

Nationwide coverage

Stay compliant and protect your workforce. Our BOHS-certified engineers provide coverage across the UK.

LEV FAQs

Your Questions Answered

From legal requirements to testing frequency, get clear answers to the most frequently asked questions about LEV compliance.

LEV testing is a legal requirement.

Regulation 9 of the COSHH Regulations states that all LEV systems must be tested, monitored, and maintained to ensure they remain in good working order.

These thorough examinations must be carried out at least once every 14 months to stay compliant.

LEV Testing Specialists

What is LEV Testing?

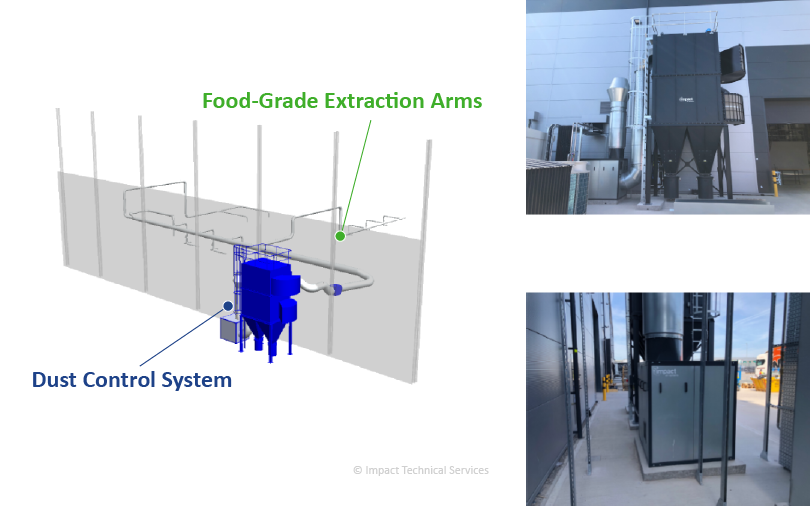

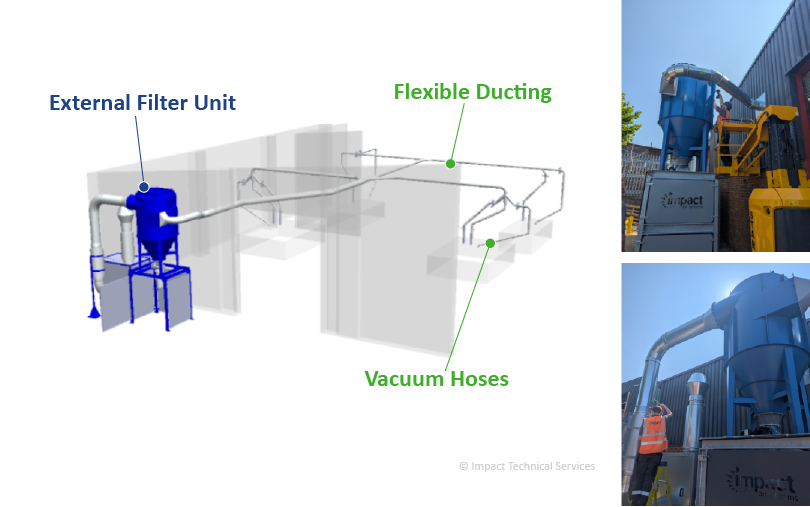

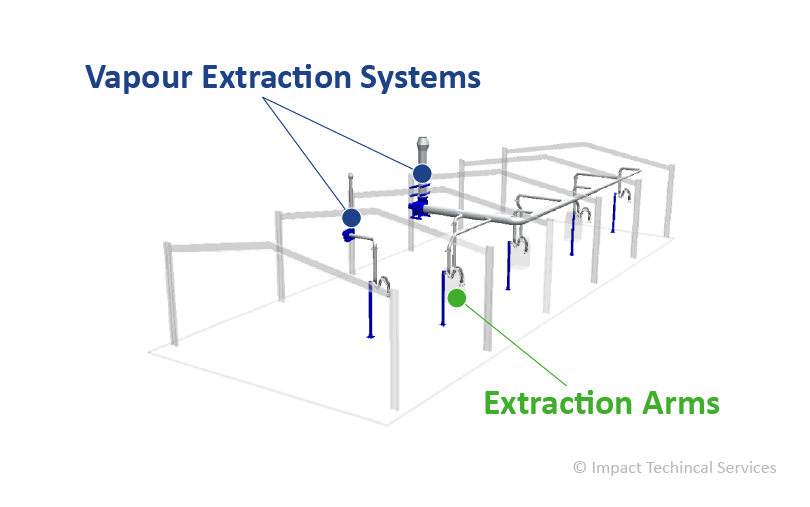

LEV testing is a comprehensive inspection and performance assessment of dust and fume extraction systems, ensuring they continue to protect workers from exposure to hazardous airborne substances.

The process involves checking the condition and integrity of key components—including ducts, hoods, filters, and airflow paths—along with measuring system performance and evaluating overall functionality in line with COSHH (Control of Substances Hazardous to Health) regulations.

To ensure accurate and reliable results, technicians use a range of specialist instruments, including:

- Anemometers for airflow measurement

- Manometers and pitot tubes for pressure checks

- Smoke testers and beam torches for visual flow tracing

- Fan rotation tools to confirm correct fan direction

- Particle counters to assess airborne contaminant levels

Proper LEV testing helps ensure systems are operating efficiently and remain compliant with legal standards—safeguarding both health and productivity in the workplace.

Our LEV Testing Process

Book Your Test

Get in touch with us today and we’ll arrange a date and time that works best for you.

Thorough Examination

A P601–P604 certified engineer will visit your site to check the work needed, inspecting hoods, ducts, filters, fans, and airflow, and then guide you on the next steps.

Compliance Report

We put together a HSE-compliant report with photos, schematics, and clear recommendations going forward.

Ongoing Support

We can offer repair, upgrades, and maintenance if required. Along with parts and spares.

Local Exhaust Ventilation Testing Report

What’s Included in an LEV Test Report?

- Hazardous substance details

- Workplace Exposure Limits (WELs) indentification

- Capture hood perforance (incl. Fletcher’s Nomogram)

- Airflow and pressure measurements

- Schematic drawings and labelled test points

- Photographs of system components

- Instrument calibration certification

- Clear defects and recommendations with action priority levels

LEV Testing Costs

How much does LEV testing cost?

The cost of LEV testing depends on the size and complexity of your system.

Smaller systems with a single extraction point can start from just £250, while larger multi-point or complex systems are quoted individually.

Why choose us?

- Clear, transparent pricing with no hidden costs

- Local engineers across the UK to reduce travel expenses

- BOHS-certified professionals

- Comprehensive, HSE-compliant reports

What are my responsibilities as an employer?

To comply with COSHH Regulations, employers are legally required to ensure that all LEV (Local Exhaust Ventilation) systems undergo Thorough Examination and Testing (TExT) at least once every 14 months. In addition, systems must be kept in good working order, and records of all tests, maintenance, and repairs must be retained for a minimum of five years.

How We Can Help:

- LEV Testing (TExT) – Full inspection and performance testing in line with HSE requirements

- LEV Maintenance & Monitoring – Ongoing servicing to keep systems running efficiently

- LEV Design & Installation – Custom solutions tailored to your workplace and compliance needs

Let us support your compliance and keep your workforce protected.

Industry-Specific LEV Testing

Industries We Work In

We provide LEV testing across all sectors, inculding:

Manufacturing

Education

Print & Packaging

Metalworking

Woodworking

Food

Security & Defence

FM/H&S

Recycling

Automotive & Vehicle

Pharmaceutical

Composites

LEV Testing FAQs

More Frequently Asked Questions

Why does my LEV system need to be tested?

Under health and safety law, employers must assess risks posed by hazardous substances and implement appropriate measures to protect their workforce.

If your workplace relies on a Local Exhaust Ventilation (LEV) system to control dust, fumes, or vapours, it is essential that the system is properly maintained to ensure continued effective protection. Furthermore, a Thorough Examination and Test (TExT) of the LEV system must be carried out at least once every 14 months in accordance with legal requirements.

How often should LEV testing be carried out?

Most LEV systems should be tested at least once every 14 months. However, regular testing is recommended to ensure your system remains effective, especially in demanding processes.

How long does an LEV test take?

The duration of an LEV test can vary depending on the complexity and size of the system. For most standard systems, testing usually takes between 1 and 3 hours. Larger or more complex systems may take longer, especially if multiple extraction points or processes need to be checked.

Do I need airflow indicators?

Although airflow indicators are not a legal requirement, employers must ensure their LEV systems consistently operate at the correct performance standard. A reduction in airflow—caused by issues such as duct damage, material buildup, or blockages—can compromise the system’s effectiveness, placing employees at risk of exposure to harmful substances.

Airflow indicators offer an immediate, visual confirmation that the system is functioning correctly, allowing employers to quickly identify and address airflow problems. This helps provide reassurance that the workforce is protected at all times.

The HSE’s LEV guidance (HSG258) explicitly recommends the use of airflow indicators as the only reliable method for instantly detecting airflow faults, making them a valuable component of any effective LEV system.

Who conducts the LEV testing and examination?

Our examiners are highly skilled professionals, equipped with the expertise, qualifications (BOHS P601-604), and experience necessary to conduct a comprehensive examination and test of your LEV system.

Drawing on detailed information from your system’s installation and previous inspections, they assess whether it continues to meet the required performance standards. Following the examination, you will receive a clear, concise report outlining your system’s compliance status, any identified issues, and recommended corrective actions.

As an employer, it is essential to:

- Carefully review and understand the report.

- Seek clarification if any aspects are unclear.

- Promptly implement any recommended actions to ensure your LEV system remains fully effective and compliant.

Do I need to keep the LEV test report?

By law, employers are required to keep a copy of their LEV examination and test (TExT) report readily available on-site.

Our examiners adhere strictly to the HSE Approved Code of Practice, ensuring your report includes all essential information—such as the system’s performance relative to its original design specifications. This report serves as a legally compliant record, demonstrating that your LEV system has been properly examined and tested in line with current regulations.

Why are LEV systems labelled after testing?

Although labelling is not a legal requirement, COSHH regulations clearly state that employers must maintain LEV system performance and carry out thorough examinations at least once every 14 months.

These labels serve as a visible record of the most recent inspection date and the next due test, helping to keep your compliance on track. They also provide an immediate alert to employers, supervisors, and operators if the system has failed, ensuring any necessary remedial action can be taken without delay.

What happens if my LEV system fails?

If an LEV system fails its test, it isn’t effectively controlling hazardous substances. The problem needs to be fixed promptly to keep staff safe and remain compliant.

This usually involves identifying the issue, making necessary repairs, and retesting the system before it can be used again.

Is testing different from servicing?

Yes. Testing checks that your system is working effectively, while servicing keeps it maintained and fixes any issues. Both are important to stay safe and compliant.

Our Latest LEV Projects

You’re in safe hands

Customer reviews

LEV experts

“I would like to commend your LEV assessor that visited our site this week. He had a very professional attitude to his job and was very patient in answering all questions that where asked of him by way of LEV auditing/testing and compliance. An impressive reflection on the service that you provide as a company…”

HSE-ISO Manager, Packaging manufacturer – Birmingham

“Your engineers were brilliant! Courteous, polite, professional and a pleasure to work with. We now have a happy building user and I am happy!…”

Project Officer, Ministry of Defence – Larkhill

“Thank you so much, we really appreciate it. It’s been a real pleasure to work with you, and we will definitely be using you in the future.”

Trish Cartwright – Limbtex

“Just wanted to drop you a quick email to say thanks for yesterday and pass on my thanks to Kam too, he didn’t stop grafting all day and did a really good job of keeping the powder to a minimum, very impressed with the service all round.”

David Tierney – Protein Works

“Credit, where credit is due, the overall experience of working with you has been great and we can’t fault your professionalism. Thank your engineer for turning up on time today in a polite and experienced manner, something in the industry you don’t see much of anymore.”

Paul Humphreys – Service Supervisor, D Wardle Plant Ltd

“I’d like to thank the Impact team for their professionalism and can-do attitude during my time with Aspire. Their team, from back-office staff to technicians, has always been a pleasure to work with. Your help and expertise are greatly appreciated.”

PPM Administrator – Defence Sector

Working with industry organisations...

A message from our Operations Director

Our team of LEV technicians and service engineers are second to none and do us proud daily. We guarantee you an outstanding service from start to finish!

Tony Bosworth

Operations Director

View the following HSE documents for more information:

OUR SERVICES

LEV Related Services

LEV Testing

LEV Products

LEV Servicing

Your one stop shop

Why choose Impact

We are your one-stop-shop for all of your workplace dust, fume, vapour and oil mist extraction requirements.

We provide an unrivalled LEV testing, LEV system design, installation and maintenance service which is complemented with a wide range of dust, fume and oil mist extraction products, consumables, spares and parts.

Experienced

30 years of nationwide coverage

Qualified

P601, P602, P603, P604 qualified LEV technicians

Outstanding Service

We have a high percentage of returning customers

Expertise

Experts in LEV project management

Warranty

12 month warranty on all installations