LEV System Design & Installation

The most important part of any LEV system is the design. Quite simply, if the design isn’t right, the system will not work effectively. Thirty years of extraction system design experience make us the ideal partner to design, improve and maintain your LEV system.

LEV Statistics

Why LEV systems are important for your business

Over 12,000 workers contract lung diseases each year from breathing airborne hazardous substances in the workplace.

UK businesses can help prevent this by investing in an LEV extraction system. A simple solution can be designed and installed to work with your application effectively and efficiently, protecting workers and ensuring you are COSHH compliant.

Book LEV Test

Nationwide coverage

We cover the whole of the UK with our nationwide technicians

LEV FAQs

Find out more

Got a question about LEV? We have the answer...

LEV System Design Experts

Over 30 years of LEV system design experience

The most important part of any LEV system is the design, if the design isn’t right, the system will not work effectively. Over 30 years of LEV extraction system design experience make us perfectly placed to design or modify your LEV system.

Our team of design engineers are trained to BOHS P602 – Basic design principles of local exhaust ventilation systems (proficiency module specified by the British Occupational Hygiene Society) to ensure that the system design is not only effective but meets the requirements of industry standards. When designing a system we will consider the following factors, as specified by the HSE (Health & Safety Executive):

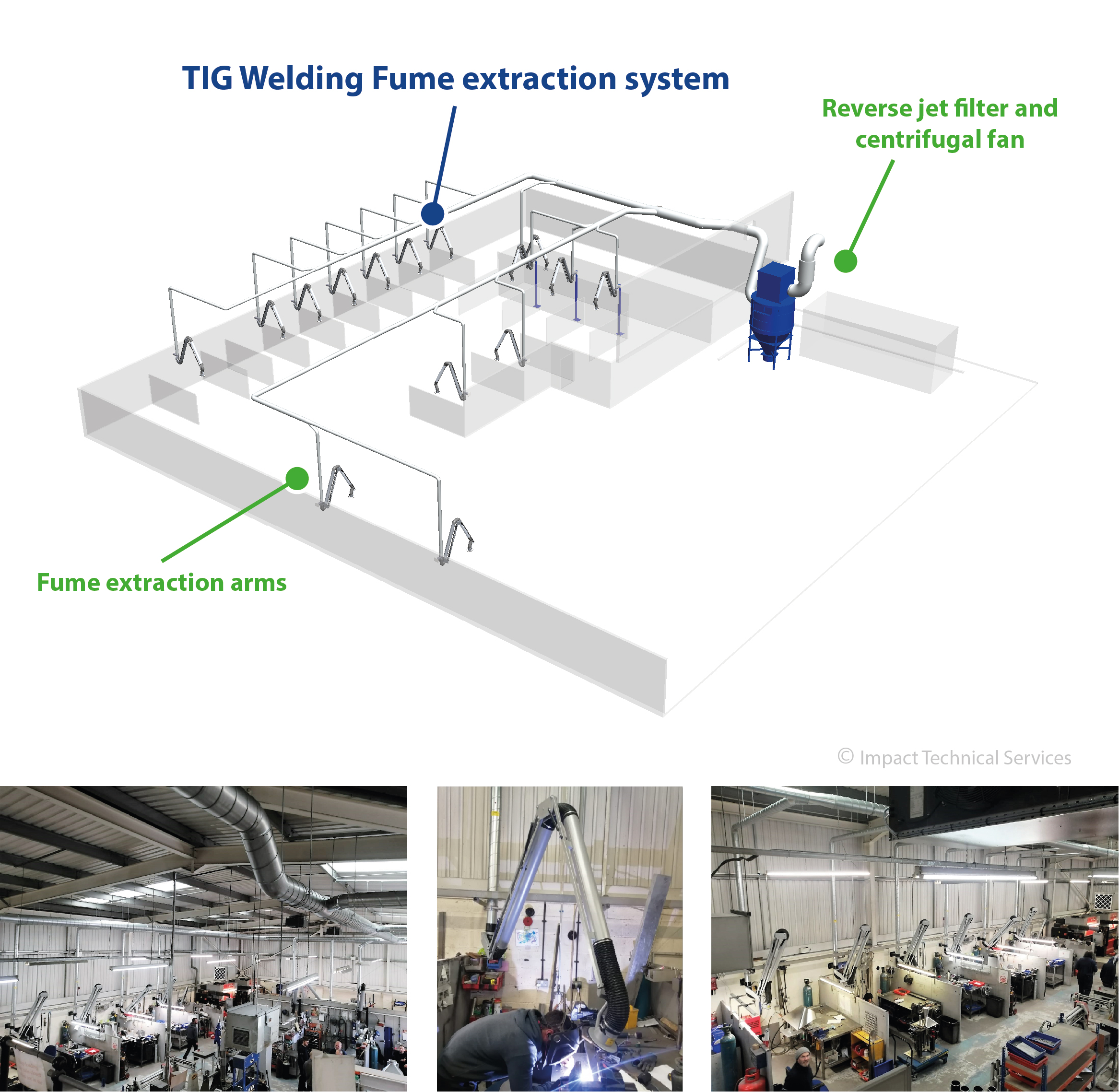

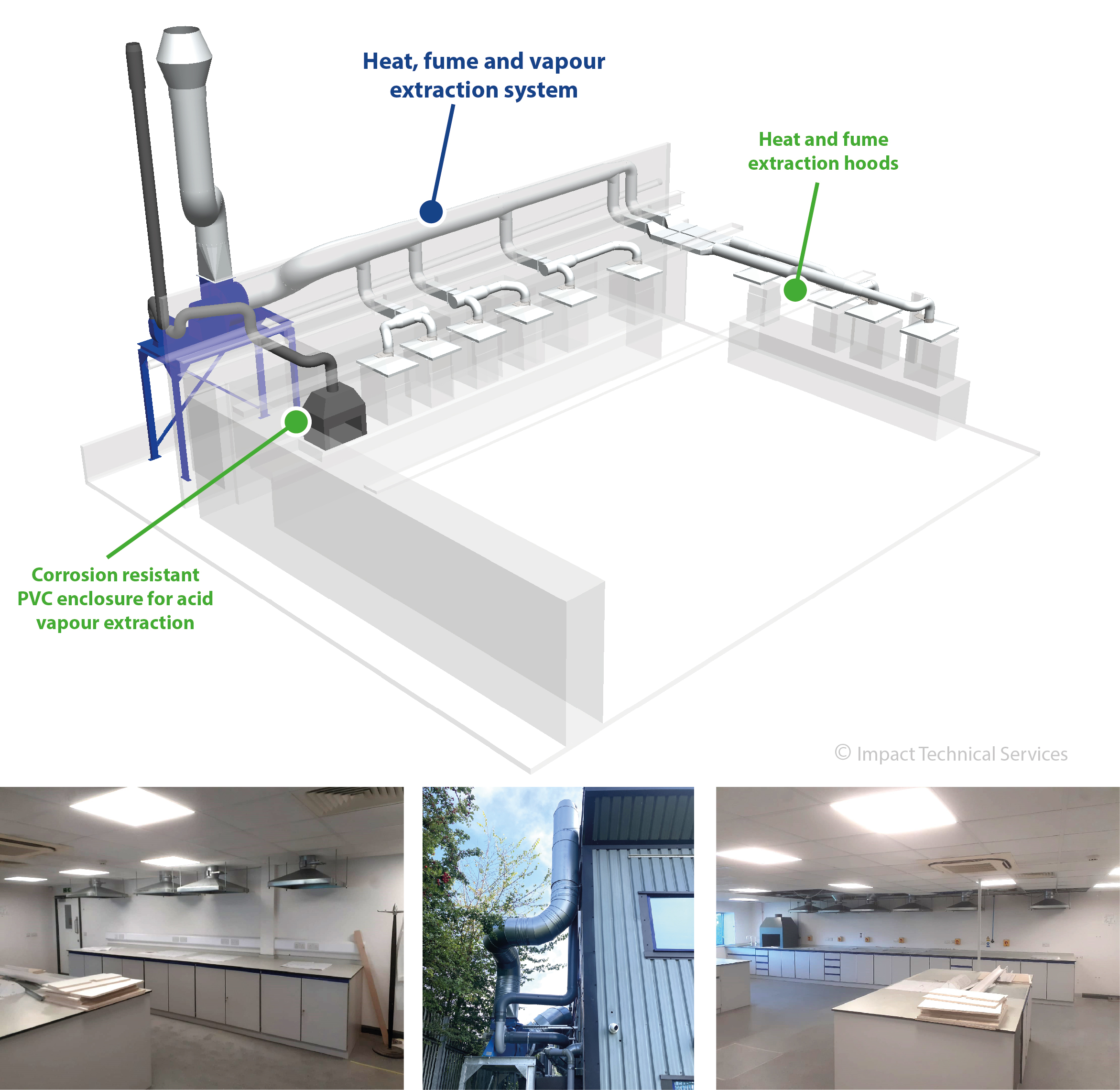

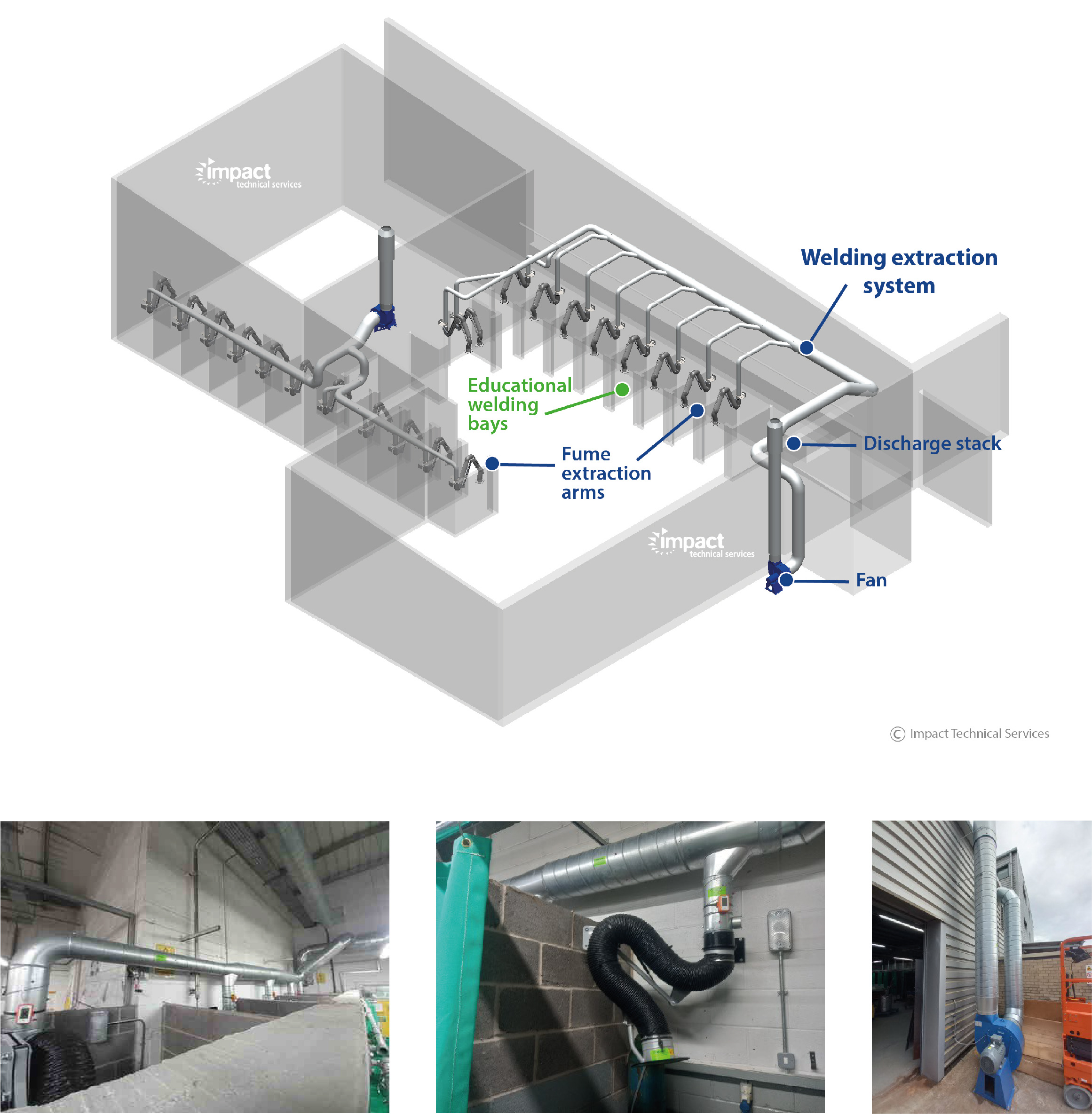

- Hood/Enclosure – to collect and contain the contaminant as close as possible to its source

- Ducts to remove the contaminant away from the source and either discharge to atmosphere or return cleaned air to the workroom

- A filter or other air cleaning device, normally placed between the hood and the fan

- A fan or other air mover to provide the airflow

LEV System Installation

Efficient, professional LEV installation & commissioning

We will install your new LEV system with minimum disruption to your manufacturing processes.

Once your LEV system has been installed we will provide you with the following (as specified by the HSE):

- Instructions for use and system diagram

- Logbook to keep track of testing and maintenance

- Commissioning report showing inlet air flow measurements, duct air speed, filter pressure drop and a maintenance guide

- Airflow indicator (optional)

- Parts and spares list i.e. filter bag replacements (available from Impact Technical Services)

Impact Will Support You At Every Step

Using your LEV system

Your LEV system is now up and running. There are a few things you need to remember to ensure reliable operation:

- Always follow the instructions provided

- Regularly look for signs of damage to the ducting, fan and filter. Any damage must be repaired immediately to ensure efficient operation

- Check weekly that the system is working properly and airflow indicators (if installed) are working

- Review failure patterns for ease of maintenance

- Contact us to book thorough examination and testing at least once every 14 months (as specified by the HSE)

Testimonial

“ITS supplied, installed and commissioned a suspended vacuum unit inside a rail depot. Installation was carried out to high quality standard and team had a excellent knowledge of equipment.

Onsite issues encountered where resolved by their collaborative approach to solving the problems. ITS had an excellent attitude to safety and documentation required in order to carry out works in a rail depot environment, e.g. inductions, permits, WPPs, RAMS, etc. All operatives understood the requirements and expectations of site rules and where responded positive to feedback. I would highly recommend ITS and we look forward to working with them in the near future.”

Working with industry organisations...

Our LEV System Design Process

We will provide you with an efficient and effective service to ensure your operations are compliant while protecting your employees. We will keep you updated throughout the installation process and continue to provide ongoing support.

A message from our LEV Sales and Design Manager

By gaining an understanding of your process and hazardous substances used, we will design and install a system that is effective, efficient & compliant

Kieren Hebborn

LEV Sales and Design Manager

Latest LEV Case Studies

We offer a wide range of LEV solutions

We specialise in designing and implementing systems for a variety of applications, including flour dust, vehicle exhaust fume, chemical fume, ATEX dust and fume, solder fume, wood waste, and composite dust.

Our experience includes designing centralised dust and fume control systems, mobile extraction units, spray booths, fume cupboards, workstation extraction, high vacuum extraction, and dust collectors.

- Centralised dust and fume control systems: These systems are designed to manage dust and fumes from multiple sources in one central location. We can design and install a custom solution that meets your specific needs.

- Mobile extraction units: Our mobile extraction units are designed for applications where a fixed extraction system is not feasible. These units are self-contained and can be moved around to different locations as needed.

- Spray booths: We design and build spray booths for a variety of applications, including automotive and aerospace. Our booths are designed to meet all relevant safety and environmental regulations.

- Fume cupboards: We design and build fume cupboards for laboratories and industrial applications. Our fume cupboards are designed to provide a safe working environment and comply with all relevant regulations.

- Workstation extraction: Our workstation extraction systems are designed to provide local extraction at individual workstations. This ensures that any dust or fumes generated during the work process are captured at the source.

- High vacuum extraction: High vacuum extraction systems are designed for applications where large volumes of air need to be moved. Our systems are designed to provide maximum airflow and suction power to ensure effective extraction.

- Dust collectors: We design and install dust collectors for a variety of applications, including woodworking and metalworking. Our dust collectors are designed to provide efficient and effective dust control while minimizing energy consumption.

- ATEX dust and fume: ATEX dust and fume systems are designed to meet the specific safety requirements for handling explosive dust and fumes. We can design and install a system that meets all relevant ATEX regulations.

View the following HSE documents for more information:

OUR SERVICES

LEV Related Services

LEV Services

LEV Products

Servicing

Your one stop shop

Why choose Impact

We are your one-stop-shop for all of your workplace dust, fume, vapour and oil mist extraction requirements.

We provide an unrivalled LEV testing, LEV system design, installation and maintenance service which is complemented with a wide range of dust, fume and oil mist extraction products, consumables, spares and parts.

Experienced

30 years of nationwide coverage

Qualified

P601, P602, P603, P604 qualified LEV technicians

Outstanding Service

We have a high percentage of returning customers

Expertise

Experts in LEV project management

Warranty

12 month warranty on all installations